| Customization: | |

|---|---|

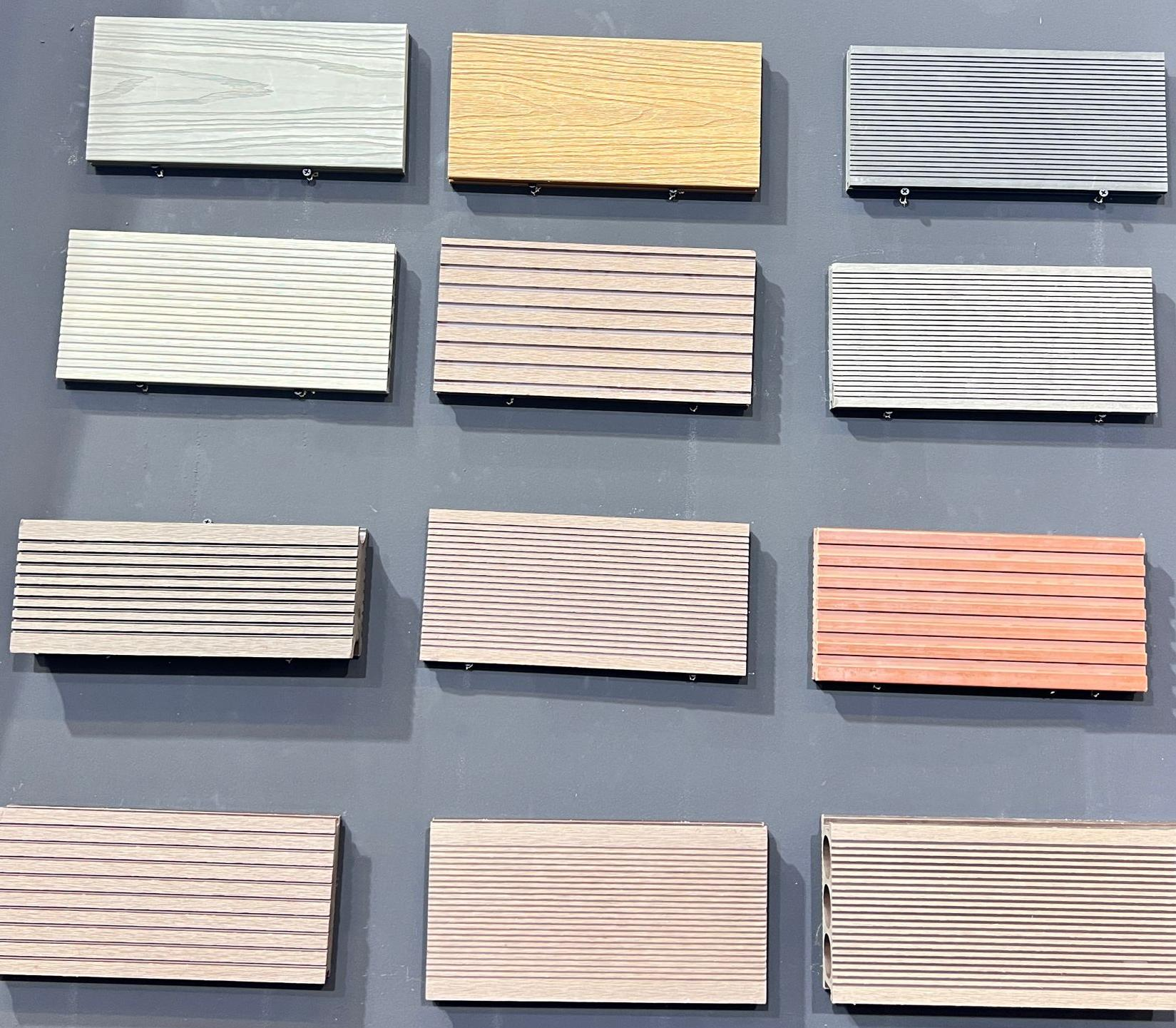

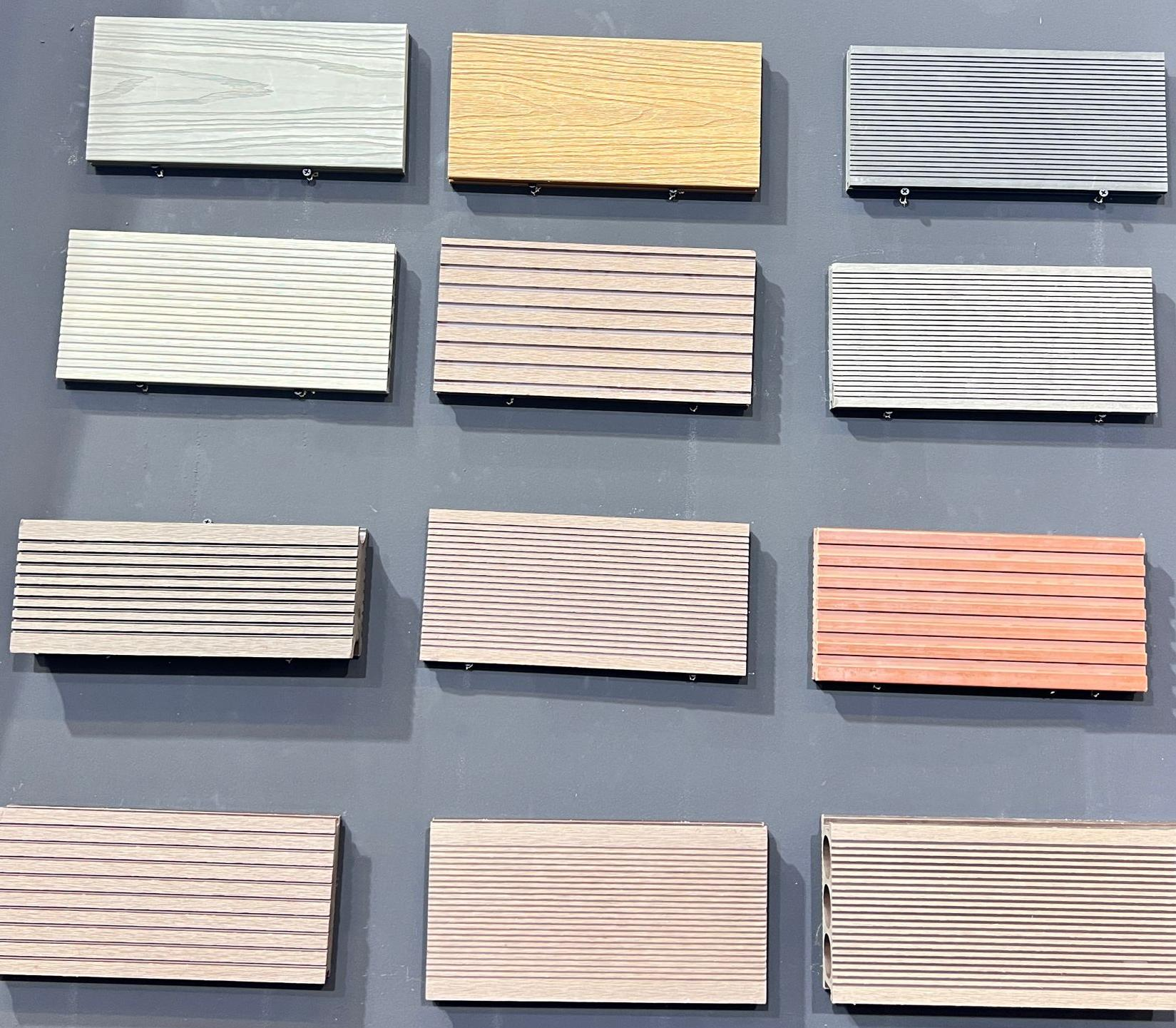

| Color: | |

| MOQ: | |

| Lead time: | |

| Availability: | |

143x22.5

VIDAR

39259000

>Indroduction

Our Foberria WPC (Wood Plastic Composites) decking 100% recyclable ,Eco-friendly ,saving forest resources.

With the look of the natural wood but no timber problems.Waterproof ,no rotten ,proven under salt water condition etc.

Barefoot friendly ,Anti-skidding ,no cracking ,no warping.No painting , no glue , low maintenance.

Available in different colors.Easy to Install and Clean.Life time more than 15 years.

>Our co-extruded wpc decking

The co-extruded wood is lighter in quality and weight than the first generation. Like plastic wood materials, the labor efficiency in the whole process of transportation is generally relatively large, especially in the solid core board, which must be 2~3 workers can work together. The lighter weight of co-extruded wood not only alleviates the labor compressive strength of workers, but also effectively saves labor costs, and the load on walls and other engineering buildings is also reasonably alleviated.

The anti-fading co-extruded wood protective layer process is unique, the proportion of anti-ultraviolet components is high, compared with traditional plastic wood, the color is more durable, and the color fastness is better. High-quality wood materials are generally installed in about 2-3 years, there will be mild large-scale fading, and there will be errors in the initial tone, which also makes many community owners very headache. The co-extruded wood ensures this, and the thickness of the tonal protective layer on the surface increases the tonal retention time to about 10 years.

It fundamentally solves the problem that wood products are prone to decay andswelling after being damp and damp in a multi-water environment, and can beused in an environment where traditional wood products cannot be applied.

>What is the difference between normal WPC decking and Co-Extrusion boards?

Normal deck boards are the first generation composite decking boards.

Co-extrusion or capped deck boards are WPC second generation boards. They have been designed with a cover that is bonded at the core of the board during manufacturing.

>Indroduction

Our Foberria WPC (Wood Plastic Composites) decking 100% recyclable ,Eco-friendly ,saving forest resources.

With the look of the natural wood but no timber problems.Waterproof ,no rotten ,proven under salt water condition etc.

Barefoot friendly ,Anti-skidding ,no cracking ,no warping.No painting , no glue , low maintenance.

Available in different colors.Easy to Install and Clean.Life time more than 15 years.

>Our co-extruded wpc decking

The co-extruded wood is lighter in quality and weight than the first generation. Like plastic wood materials, the labor efficiency in the whole process of transportation is generally relatively large, especially in the solid core board, which must be 2~3 workers can work together. The lighter weight of co-extruded wood not only alleviates the labor compressive strength of workers, but also effectively saves labor costs, and the load on walls and other engineering buildings is also reasonably alleviated.

The anti-fading co-extruded wood protective layer process is unique, the proportion of anti-ultraviolet components is high, compared with traditional plastic wood, the color is more durable, and the color fastness is better. High-quality wood materials are generally installed in about 2-3 years, there will be mild large-scale fading, and there will be errors in the initial tone, which also makes many community owners very headache. The co-extruded wood ensures this, and the thickness of the tonal protective layer on the surface increases the tonal retention time to about 10 years.

It fundamentally solves the problem that wood products are prone to decay andswelling after being damp and damp in a multi-water environment, and can beused in an environment where traditional wood products cannot be applied.

>What is the difference between normal WPC decking and Co-Extrusion boards?

Normal deck boards are the first generation composite decking boards.

Co-extrusion or capped deck boards are WPC second generation boards. They have been designed with a cover that is bonded at the core of the board during manufacturing.