| Customization: | |

|---|---|

| Lead time: | |

| MOQ: | |

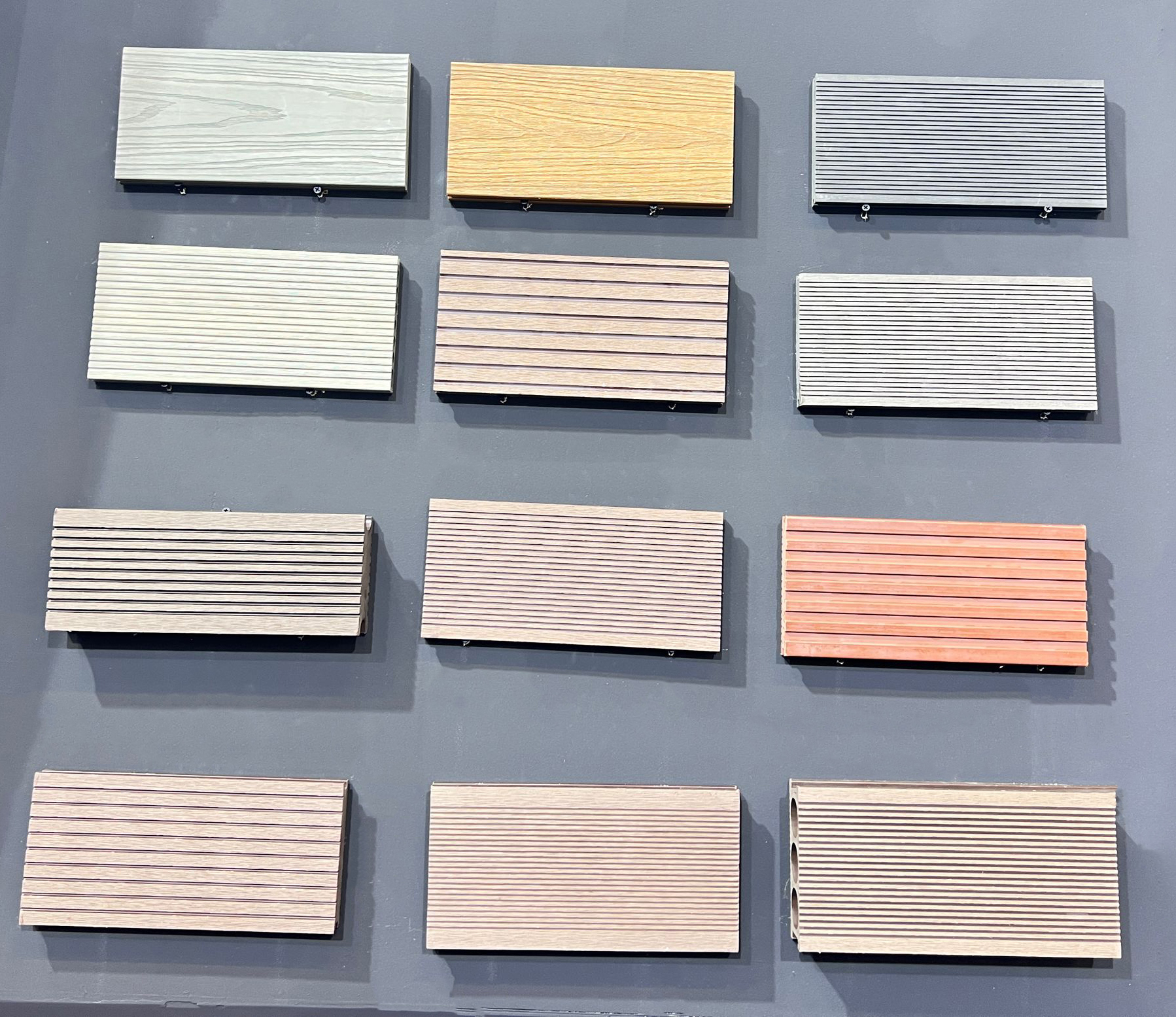

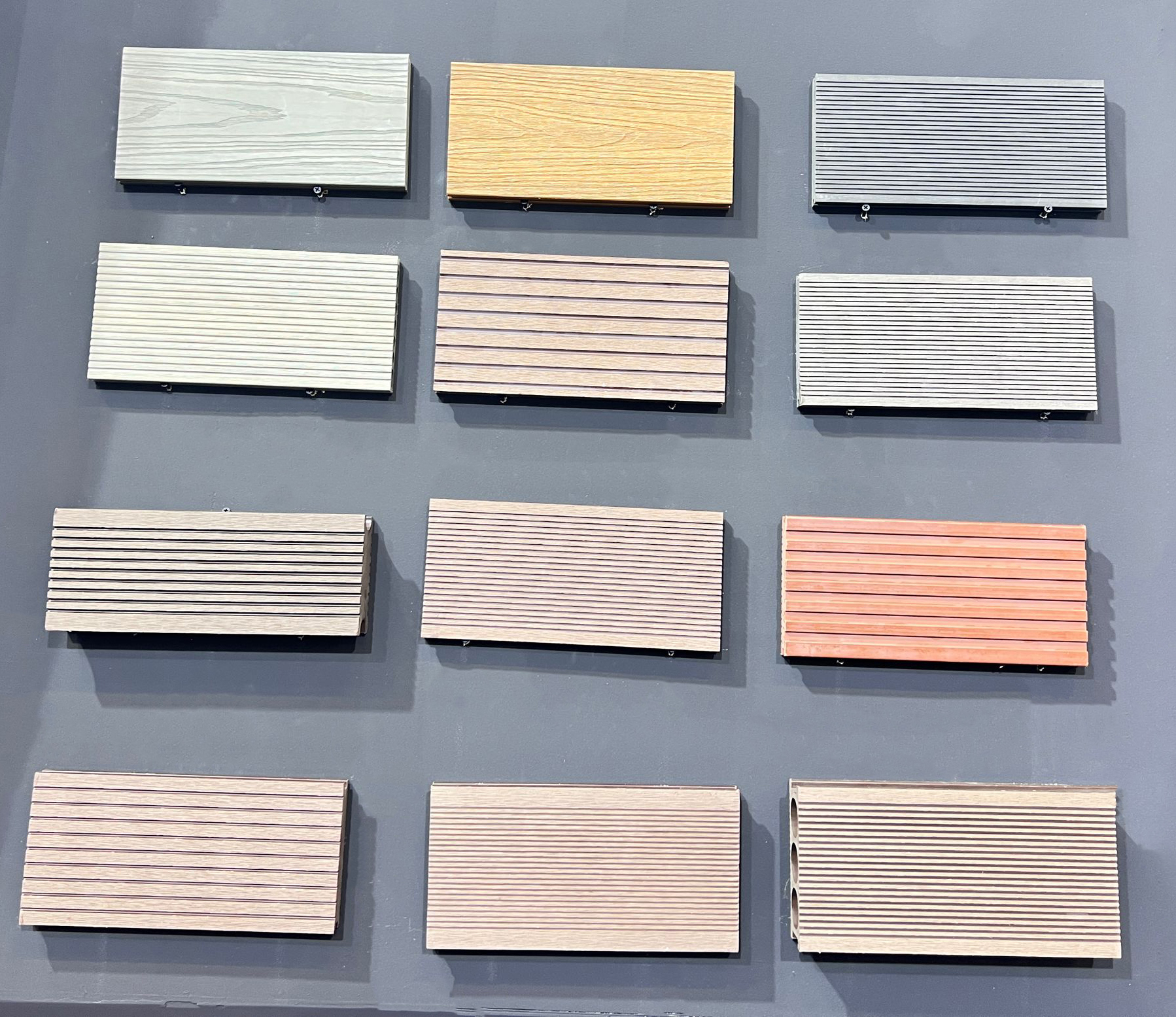

| Color: | |

| Availability: | |

145H25

VIDAR

39259000

>Procudt information

| Name | WPC Hollow Decking |

| Standard size | 145x21mm, 146x21mm, 146x31mm, 145x25mm, 150X40mm |

| WPC component | 30% HDPE+60% wood fiber + 10% additives |

| Accessories | Patented clip-easy system |

| Delivery time | About 15-20 days for one 20ft container |

| Payment | 30% deposited, the rest should be paid before deliver |

| Maintenance | Free maintenance |

| Recycling | 100% recyclable |

| Package | Pallet or bulk packing |

>WPC decking Features:

1.Dimensional stability, longevity, natural feel

2. Stable over a wide temperature range, weather-resistant

3. High impact resistant

4. Environmentally friendly, recyclable

5. Board range of finishes and appearance

6. Easily produced and easily fabricated

7. Contains no toxic chemicals or preservatives

8. Resistance to rot and crack

9. Moisture resistant, low flame spread

10. Outstanding screw and nail retention

>How to installation?

Step 1: Lay the keels one by one, ensuring that the distance between the keels is about 30-35cm.

Step 2: Make holes on the keel, and screw the solid nails into the holes.

Step 3: Fix the starting buckle on the edge of the keel,drive in the screws,and after fixing.

Step 4: Start laying the plastic wood floor. Place the first floor horizontally and perpendicularly to the keel, and the initial buckle is clamped in the groove of the floor to fix one side of the first plastic wood floor.

Step 5: Lay the second row of floors,insert the plastic buckle into the groove between the two floors, move it to the middle of the keel, insert the correspondina number of fasteners according to the number of keels and use a pistol drill to drive the screws into the fasteners and fix the keel.

Step 6: And soon for the floor behind.

Step 7: When the last piece of floor is fixed on the keel with screws diagonally, and finally the floor is nailed to seal the edge, it is done.

>Procudt information

| Name | WPC Hollow Decking |

| Standard size | 145x21mm, 146x21mm, 146x31mm, 145x25mm, 150X40mm |

| WPC component | 30% HDPE+60% wood fiber + 10% additives |

| Accessories | Patented clip-easy system |

| Delivery time | About 15-20 days for one 20ft container |

| Payment | 30% deposited, the rest should be paid before deliver |

| Maintenance | Free maintenance |

| Recycling | 100% recyclable |

| Package | Pallet or bulk packing |

>WPC decking Features:

1.Dimensional stability, longevity, natural feel

2. Stable over a wide temperature range, weather-resistant

3. High impact resistant

4. Environmentally friendly, recyclable

5. Board range of finishes and appearance

6. Easily produced and easily fabricated

7. Contains no toxic chemicals or preservatives

8. Resistance to rot and crack

9. Moisture resistant, low flame spread

10. Outstanding screw and nail retention

>How to installation?

Step 1: Lay the keels one by one, ensuring that the distance between the keels is about 30-35cm.

Step 2: Make holes on the keel, and screw the solid nails into the holes.

Step 3: Fix the starting buckle on the edge of the keel,drive in the screws,and after fixing.

Step 4: Start laying the plastic wood floor. Place the first floor horizontally and perpendicularly to the keel, and the initial buckle is clamped in the groove of the floor to fix one side of the first plastic wood floor.

Step 5: Lay the second row of floors,insert the plastic buckle into the groove between the two floors, move it to the middle of the keel, insert the correspondina number of fasteners according to the number of keels and use a pistol drill to drive the screws into the fasteners and fix the keel.

Step 6: And soon for the floor behind.

Step 7: When the last piece of floor is fixed on the keel with screws diagonally, and finally the floor is nailed to seal the edge, it is done.